Mechanical Engineering

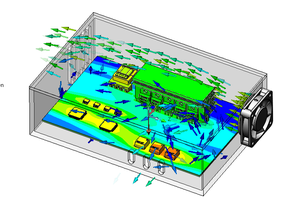

As part of our comprehensive range of development services - from the idea to series production - we also offer housing designs for electronic modules.

This includes the production- and assembly-oriented construction of individual parts and assemblies up to complete devices. We supervise the construction of samples and pilot series.

Engineering Services

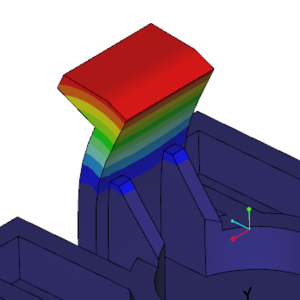

- Robust injection moulded, die-cast and sheet metal housings

- Explosion-proof enclosures

- Pressure resistant housing

- Pressurised encapsulation

- Encapsulation

- Dustproof

- Switch cabinet housing

- Electromechanical assemblies

- Weatherproof housing

- Assembly jigs